Birck Nanotechnology Center Overview

Discovery Park at Purdue University

The Birck Nanotechnology Center is one of ten core centers in Purdue's $375M, 40-acre Discovery Park. Discovery Park provides an intellectual environment and facilities for multidisciplinary approaches to interdisciplinary challenges and opportunities spanning the domains of energy, the environment, healthcare, economic development, information access and homeland security. Discovery is intimately coupled with delivery in Discovery Park. Whether it be commercialization, community outreach, public policy, K-12 education or clinical translation, researchers in Discovery Park have their sights set on impact, and the resources and expertise needed to expedite the process to impact are integrated into the fabric of Discovery Park.

The Birck Nanotechnology Center is one of ten core centers in Purdue's $375M, 40-acre Discovery Park. Discovery Park provides an intellectual environment and facilities for multidisciplinary approaches to interdisciplinary challenges and opportunities spanning the domains of energy, the environment, healthcare, economic development, information access and homeland security. Discovery is intimately coupled with delivery in Discovery Park. Whether it be commercialization, community outreach, public policy, K-12 education or clinical translation, researchers in Discovery Park have their sights set on impact, and the resources and expertise needed to expedite the process to impact are integrated into the fabric of Discovery Park.The Birck Nanotechnology Center

The Birck Nanotechnology Center (BNC) is an interdisciplinary research unit that provides infrastructure for 160 affiliated faculty members and their research groups from 36 academic units at Purdue. The 186,000 sq ft. facility includes a 25,000 sq. ft. ISO Class 3-4-5 (Class 1-10-100) nanofabrication cleanroom – the Scifres Nanofabrication Laboratory – that includes a 2,500 sq. ft. ISO Class 6 (Class 1000) pharmaceutical-grade biomolecular cleanroom. In addition to the cleanroom, the facility provides 22,000 sq. ft. of specialized laboratories and offices for 45 resident faculty members, 30 post-docs, 30 staff, and approximately 200 graduate students. A flexible Nanotechnology Incubator lab may be leased by companies through the Purdue Research Foundation. All of the equipment in the BNC is shared, and is accessible to qualified and trained users from Purdue and from academic, industrial, and government laboratories outside Purdue. Most of the major equipment is available through recharge centers that support maintenance, supplies, and support staff.

The Birck Nanotechnology Center (BNC) is an interdisciplinary research unit that provides infrastructure for 160 affiliated faculty members and their research groups from 36 academic units at Purdue. The 186,000 sq ft. facility includes a 25,000 sq. ft. ISO Class 3-4-5 (Class 1-10-100) nanofabrication cleanroom – the Scifres Nanofabrication Laboratory – that includes a 2,500 sq. ft. ISO Class 6 (Class 1000) pharmaceutical-grade biomolecular cleanroom. In addition to the cleanroom, the facility provides 22,000 sq. ft. of specialized laboratories and offices for 45 resident faculty members, 30 post-docs, 30 staff, and approximately 200 graduate students. A flexible Nanotechnology Incubator lab may be leased by companies through the Purdue Research Foundation. All of the equipment in the BNC is shared, and is accessible to qualified and trained users from Purdue and from academic, industrial, and government laboratories outside Purdue. Most of the major equipment is available through recharge centers that support maintenance, supplies, and support staff.Viewgraphs: Orientation to Birck Nanotechnology Center

The Scifres Nanofabrication Laboratory

Cleanroom. The nanofabrication cleanroom consists of 25,000 sq. ft. of bay-chase cleanroom, with 45% of the bays operating at ISO 3 (Class 1), 40% operating at ISO 4 (Class 10), and the remaining 15% operating at ISO 5 (Class 100). The three-level structure consists of a full subfab, the cleanroom level, and an air-handling level above the cleanroom. A perforated raised floor ensures unidirectional airflow and bulkhead-mounted equipment separates operational functions from maintenance functions. A combination of careful control of the airflow path, multiple stages of filtration, careful choice of materials, and non-ionic-steam humidification ensure the control of both particulate and molecular contamination. A very tight waffle slab provides NIST “A” vibration rating, approximating quiet, slab-on-grade construction.

Cleanroom. The nanofabrication cleanroom consists of 25,000 sq. ft. of bay-chase cleanroom, with 45% of the bays operating at ISO 3 (Class 1), 40% operating at ISO 4 (Class 10), and the remaining 15% operating at ISO 5 (Class 100). The three-level structure consists of a full subfab, the cleanroom level, and an air-handling level above the cleanroom. A perforated raised floor ensures unidirectional airflow and bulkhead-mounted equipment separates operational functions from maintenance functions. A combination of careful control of the airflow path, multiple stages of filtration, careful choice of materials, and non-ionic-steam humidification ensure the control of both particulate and molecular contamination. A very tight waffle slab provides NIST “A” vibration rating, approximating quiet, slab-on-grade construction.Lithography. Lithographic capability spans the nano and micro scale, with the capability of integrating nanoscale structures within micro-scale devices. A Vistec VectorBeam VB-6 UHR-UWF electron-beam lithography system provides the capability of 6 nanometer lines in resist across a 1.3 mm field and a Raith e-beam nanolithography system provides 20 nanometer resolution. An interference lithography system provides 100 nanometer resolution for less-critical operations. A nanoimprint-lithography tool replicates images created on the e-beam lithography system. Optical lithography is used in many operations in BNC, and is supported by a maskmaking operation and single- and double-sided mask alignment. A Heidelberg laser maskmaking system and a 5x Criss-Cross Pattern Generator/Step-and-Repeat system, coupled with specialized image-reversal systems, provide a variety of photomasks to support research efforts.

Etching. Wet- and dry-etch capabilities allow the etching at high aspect ratios in a variety of materials. Three STS Deep Reactive Ion Etch (DRIE) systems, a Panasonic chlorine-fluorine DRIE, a xenon difluoride etcher, and an Oxford PlasmaTech system anchor the dry-etching capabilities. A Branson asher removes photoresist by use of an oxygen plasma. Several conventional acid and solvent hoods, as well as two high-temperature-acid hoods, provide space for wet etches and cleans.

Deposition. Physical vapor deposition is a strength in the BNC. Eight evaporators and four sputterers allow the deposition of more than 24 different materials. Additionally, plasma-enhanced deposition systems and an LPCVD system provide further capabilities. Of special interest are four atomic-layer-deposition (ALD) systems designed especially for high-integrity high-k dielectric films.

Furnaces. Three three-tube banks of process furnaces include clean (i.e., gate) oxidation, drive, LTO, and LPCVD capabilities. This is supplemented by a separate two-tube pyrogenic oxidation system and several smaller high-temperature tubes and lower-temperature annealing tubes. Low temperature annealing and activation can be performed on three rapid-thermal-processing systems.

Ultra-Pure Water. The ultra-pure water (UPW) system at BNC supplies all laboratories and the cleanroom with incredibly pure water. Termed nano-grade water, this water is below the measurement limits of 15 parts per trillion of boron, the ion most loosely bound to the mixed beds and therefore the most likely ionic impurity in the water. This water also contains less than 225 parts per trillion of total oxidizable carbon (TOC) and less than 1 part per billion of dissolved oxygen.

Biocleanroom. Integrated into the Scifres Nanofabrication Laboratory is a pharmaceutical-grade cleanroom to allow sterile processing. This cleanroom is entered through a separate gowning room and has a completely separate air-handling system, but has a pass-through to the nanofabrication cleanroom to allow materials to be transferred into this facility without breaking cleanliness. Designed for sanitization, it trades a perforated floor for coved sheet-vinyl flooring and boasts a special pharmaceutical wall and ceiling system. Outside the entrance to the biocleanroom is an enclosed overhead walkway to Bindley Bioscience Center.

Specialized Laboratory Facilities

Overview. In addition to the cleanroom, the BNC includes a suite of specialized laboratories that provide outstanding capabilities to researchers. All BNC laboratories are designed for low acoustic noise, less than 1 milligauss EMI, and +/- 1 degree C temperature stability. Additionally, the first-floor laboratories achieve NIST A vibration rating. From this base, certain laboratories have been modified to provide even more stringent limits to accommodate specialized needs. For example, the TEM laboratory has tighter temperature controls, has specialized airflow patterns, and has special acoustic materials on the walls and floors.

Overview. In addition to the cleanroom, the BNC includes a suite of specialized laboratories that provide outstanding capabilities to researchers. All BNC laboratories are designed for low acoustic noise, less than 1 milligauss EMI, and +/- 1 degree C temperature stability. Additionally, the first-floor laboratories achieve NIST A vibration rating. From this base, certain laboratories have been modified to provide even more stringent limits to accommodate specialized needs. For example, the TEM laboratory has tighter temperature controls, has specialized airflow patterns, and has special acoustic materials on the walls and floors.

Hall Nanometrology Laboratory. For highly sensitive functions, the Kevin G. Hall Nanometrology Laboratory provides enhanced control of temperature, vibration, acoustic noise, and EMI. Temperature is controlled to +/- 0.01 degree C, EMI is controlled to less than 0.1 milligauss, acoustic noise is within NC-35 criteria, and vibration is controlled to NIST A-1 criteria.

Scanning Laser-Doppler Vibrometry. A specialized laboratory that meets NIST A-1 vibration criteria houses the Scanning Laser-Doppler Vibrometer. The Polytec MSA-400 Micro System Analyzer uses a variety of methods to characterize motion in micro- and nanostructures.

Scanning Probe Microscopy. Nine atomic force microscopes provide topographical data on surfaces as well as allowing the manipulation of materials at the nano scale. Two systems are designed especially for analyzing biological samples, with one located in a BSL-1 laboratory and the other in a BSL-2 laboratory.

Electron Microscopy. Four electron microscopes provide the ability to image nanoscale devices and materials, as well as to study reaction mechanisms at the atomic scale. An FEI Titan 80-300 keV Field Emission Environmental Transmission Electron Microscope – Scanning Transmission Electron Microscope provides resolutions to 0.7 by 1.0 Angstrom units. The system contains an in-situ reaction chamber, and is equipped with a high-performance camera and data server.

Supplementing the capabilities of the Titan are an FEI Field-Emission Scanning Electron Microscope, an FEI “Novalab” Focused Ion Beam – Scanning Electron Microscope system, and a dual-function JEOL Scanning Electron Microscope with electron-beam direct-write capability.

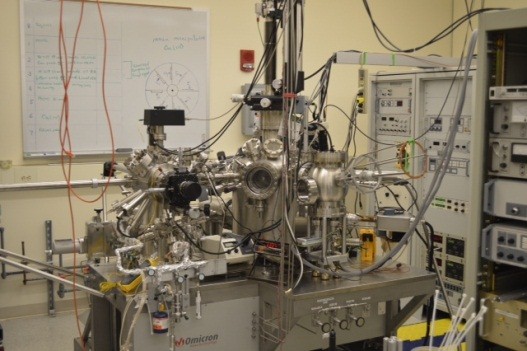

Surface Analysis. The surface analysis laboratory contains a Kratos Imaging x-Ray Photoemission Spectrometer (XPS) with an in-situ reaction cell and an Omicron surface analysis cluster tool. The XPS has a 15 micrometer spot size, and provides atomic-level analysis of materials. The cluster tool contains multiple devices to characterize the surfaces of materials, including a high-resolution electron-energy-loss spectrometer (EELS), a scanning electron microscope (SEM), a scanning auger spectrometer, a hemispherical electron spectrometer for XPS, AES, UPS, ISS, a focused ion beam (FIB) system and an Omicron UHV Scanning Tunneling Microscope – all connected under ultra-high vacuum.

x-Ray Diffraction. The x-ray diffraction laboratory contains a high-resolution PANalytical “x”Pert Pro x-ray diffraction system.

Epitaxy. Several BNC laboratories contain equipment for specialized, highly precise epitaxial growth. Two ultra-clean Molecular Beam Epitaxy systems for III-V epitaxy, an Epigress VP-508 hot-wall CVD reactor for SiC and graphene, and an Aixtron AIX 200/4 metal-organic chemical vapor deposition (MOCVD) system for GaN allow the growth of a variety of homoepitaxial and heteroepitaxial materials.

Deposition. An ASTeX plasma-enhanced chemical vapor deposition system allows film growth of specialized materials. A specialized Parylene deposition system deposits type C and N polymer onto a variety of substrates.

3D Cell Culture Core (3D3C) Facility and Biosafety Level 2 Laboratories.

The Birck Nanotechnology Center has five Biosafety Level 2 (BSL-2) laboratories. One large and two attached small tissue-culture rooms are designated as the 3D Cell Culture Core (3D3C) Facility for studies employing 3D cell culture in biology and engineering research. The facility is equipped with four cell culture hoods and equipment for cell culture (cell culture incubators, water baths, centrifuges, microscopes, etc.). The main room is also equipped with immunohistochemistry staining station and Applied Biosystems® ArcturusXT™ Laser Capture Microdissection System.

A separate BSL-2 laboratory is dedicated to bacterial culture work. The biocleanroom also houses a small BSL2 cell culture room for work requiring live cells in a pharmaceutical-grade environment. These specialized laboratories allow for the safe handling of pathogenic biological materials used in the development of devices and delivery methods.

Biosafety Level 1 and Nanochemistry Laboratories. The BNC provides three laboratories rated at biosafety level 1 (BSL-1) for less hazardous nano-bio and nanochemistry research – including the main biocleanroom space. These laboratories are used for both mechanical and wet-chemical research activities.

Electrical Characterization Laboratories. A significant amount of BNC laboratory space is allocated to electrical characterization. From an 8 Tesla, liquid-helium-cooled Hall Effect measurement system to multiple shielded probe stations with hot and cold testing capabilities, these laboratories provide the equipment and facilities necessary to evaluate new materials, structures, and devices. We also offer a Lakeshore planar magnetic probe station.

Laser Laboratories. Specialized laboratories for optical materials development, optically enhanced deposition, and optical characterization methods have been implemented in the BNC. Using lasers of various power levels – up to Class 4 – BNC researchers are able to develop materials, processes, and devices for energy conversion and other applications. These laboratories also support research strengths in nanoelectronics and nanophotonics.

Nanoincubator Laboratory. The BNC provides flexible laboratory space that can be leased by companies through the Purdue Research Foundation. This space is designed to provide a secure, specialized laboratory for companies wishing to use the infrastructure of the BNC while maintaining private laboratory space for specialized or proprietary work.